Removing support material is a critical, yet often challenging, step in the Fused Deposition Modeling (FDM) 3D printing process. While standard supports are essential for printing overhangs and complex geometries, their removal can sometimes damage the part, leaving behind an unsightly surface finish. Mastering advanced techniques can save you time, reduce waste, and lead to higher-quality final products for your prototyping and R&D projects.

Understanding FDM Supports

FDM supports are temporary structures built to prevent a part from collapsing during the printing process. They are necessary for any feature that extends outward without a layer directly below it. While most slicing software automatically generates supports, the key to successful removal lies in understanding their design and the different materials they can be made from.

Techniques for Clean Support Removal

Beyond simply snapping off the supports, there are several methods you can use to ensure a clean finish and preserve the integrity of your part:

- Manual Removal with Precision Tools: Using small flush cutters, tweezers, and craft knives allows you to carefully snip away supports from hard-to-reach areas. This method requires patience but gives you maximum control. For a smoother finish, you can follow up with light sanding or filing.

- Water-Soluble Supports (PVA): For printers with dual extruders, using a water-soluble material like PVA (Polyvinyl Alcohol) for supports is a game-changer. After printing, you simply submerge the part in water, and the support material dissolves completely, leaving a perfect, unmarred surface.

- Chemical Smoothing: Certain materials, like ABS, can be post-processed with chemicals such as acetone vapor. This technique dissolves the outermost layer of the plastic, smoothing away tiny support marks and layer lines. This requires a controlled environment and should be done with extreme caution.

- Optimizing Support Settings in Slicer Software: Before you even print, you can adjust settings in your slicing software (e.g., Cura, PrusaSlicer) to make support removal easier. By changing the "support interface" or "Z-distance," you can create a small gap between the support and the part, allowing it to peel away cleanly with less effort.

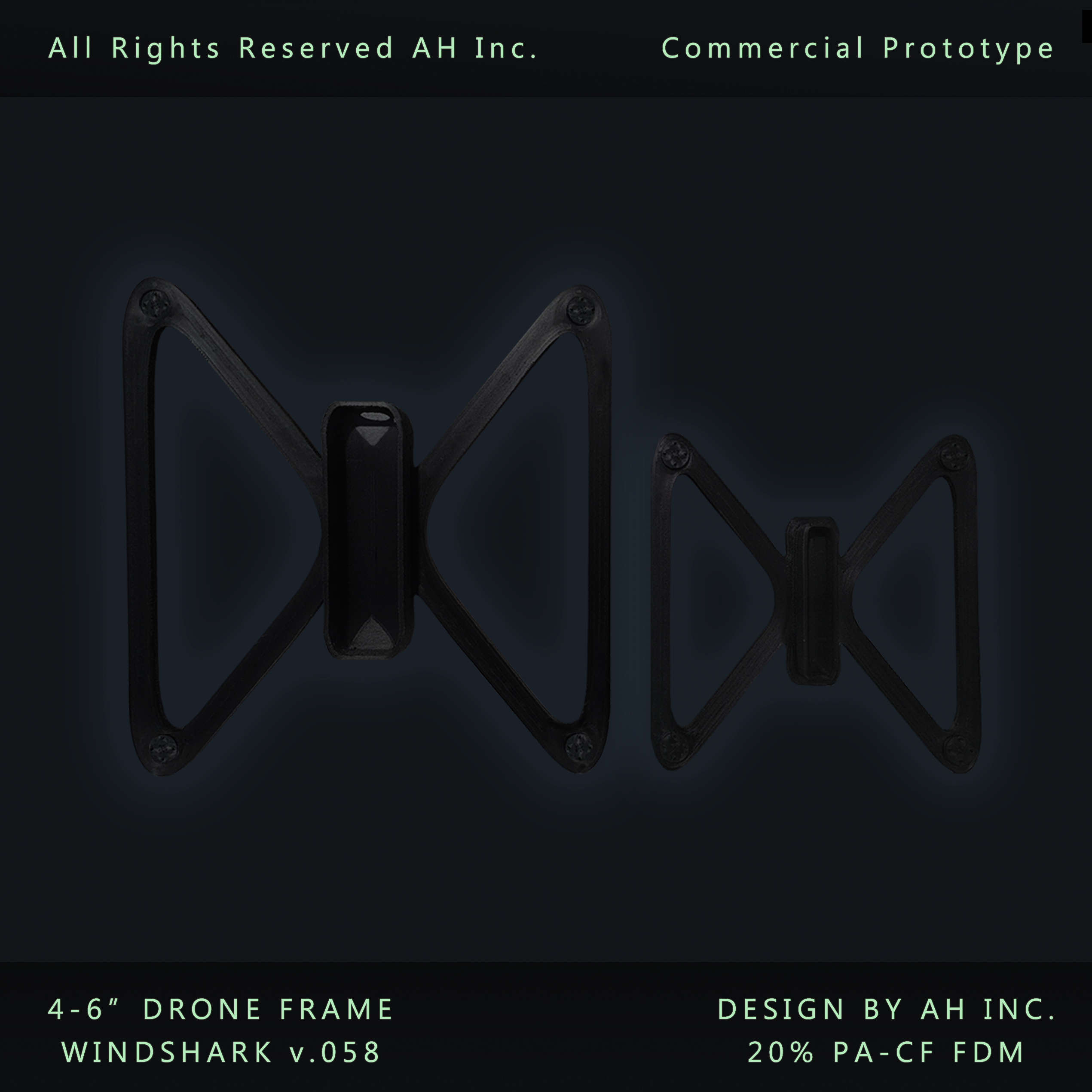

Choosing the right support removal technique depends on the material you're using, the complexity of your part's geometry, and your desired final finish. By incorporating these advanced methods into your workflow, you can elevate the quality of your batch production and confidently tackle even the most intricate FDM projects. At Agratis, our expertise in advanced FDM techniques ensures your final products are flawless, from the first prototype to large-scale batches.