Prototyping Services

Get a QuoteOur Prototyping Capabilities

FDM Prototyping

High-quality prototypes using a variety of thermoplastics.

- - Fast turnaround

- - Cost-effective

- - Wide range of materials

SLA Prototyping

Precision prototypes with smooth surfaces and fine details.

- - High accuracy

- - Excellent surface finish

- - Intricate details

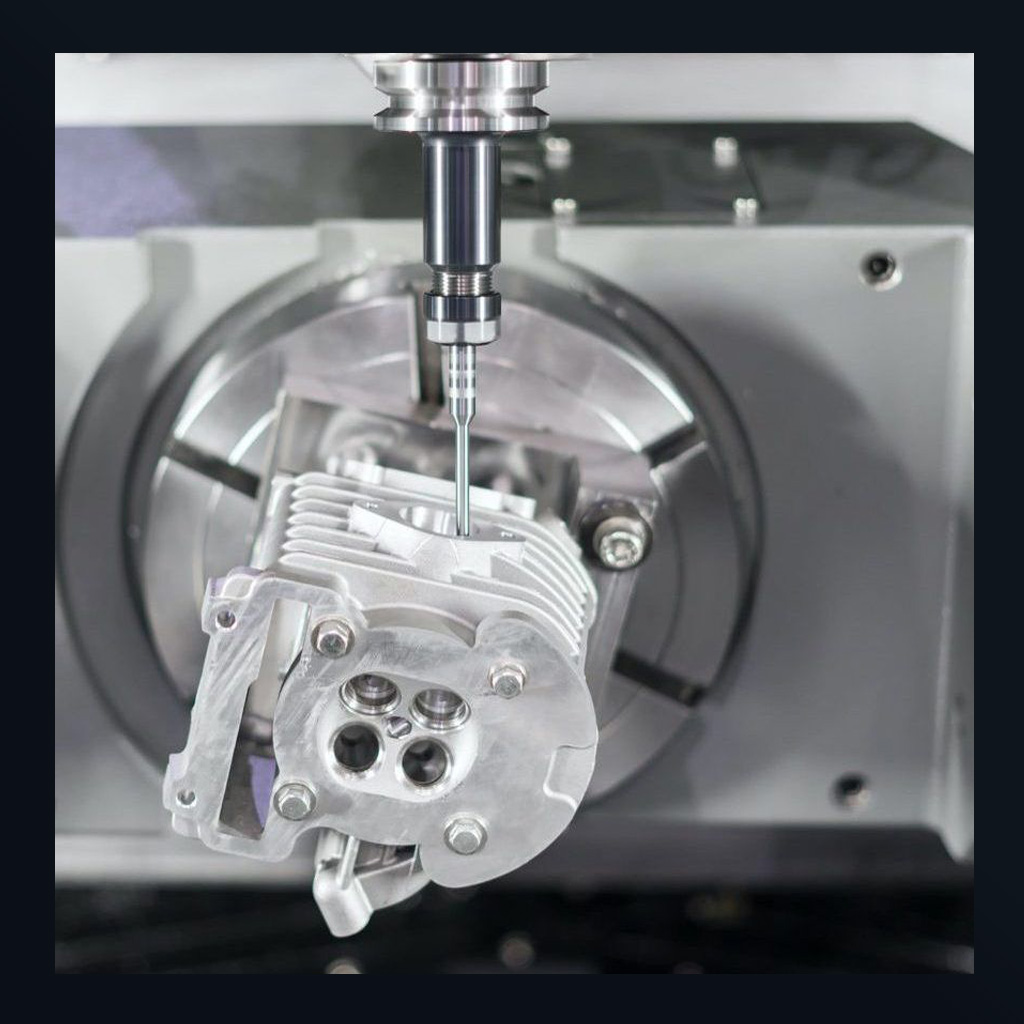

Hybrid Prototyping Solutions

Combining 3D printing with advanced production methods.

- - Enhanced Strength with Carbon Resin Infusion

- - Precision Detailing via CNC Machining

- - Complex Geometries and Features

Prototyping Solution Comparison

| Feature | FDM Prototyping | SLA Prototyping | Hybrid Prototyping |

|---|---|---|---|

| Material Variety | Wide | Limited (Resins) | Very Wide (Thermoplastics, Resins, Composites) |

| Accuracy & Detail | Good | Excellent | High to Very High (Depends on Combined Methods) |

| Surface Finish | Layer Lines Visible | Smooth | Variable (Can be Very Smooth with Post-Processing) |

| Cost | Generally Lower | Moderate | Generally Higher |

| Best For | Functional parts, rapid iterations | High-detail prototypes, smooth surfaces | Complex geometries, specific material properties |

Our Prototyping Process

Design Analysis

Our process begins with a thorough analysis of your 3D model. We meticulously examine the design for manufacturability, structural integrity, and optimal orientation for 3D printing. This crucial step helps identify potential issues early on, ensuring a smoother and more successful prototyping outcome. We provide detailed feedback and suggestions for improvements.

Material Selection

Choosing the right material is paramount for a functional and representative prototype. Our experts guide you through a wide selection of engineering-grade thermoplastics, resins, and composites, considering factors such as strength, flexibility, temperature resistance, and surface finish requirements. We provide material data sheets and recommendations tailored to your specific application.

Production & Post-Processing

Leveraging our advanced 3D printing technologies, we bring your digital design to life with precision and efficiency. Our capabilities include FDM, SLA, and hybrid methods. Following production, we offer a range of post-processing services, including support removal, cleaning, sanding, painting, and surface finishing, to achieve the desired aesthetic and functional properties of your prototype.