Welcome to the forefront of manufacturing. The world of 3D printing is constantly evolving, and at the heart of every successful print lies a perfectly tuned profile. While default settings can get you started, creating a custom 3D printing profile is the secret to unlocking the true potential of your machine and materials. This is an essential step for anyone engaged in serious R&D projects or seeking to optimize their workflow for demanding applications.

Why Custom Profiles Matter for Both FDM and SLA Printing

Default profiles are a one-size-fits-all solution, but your project is unique. By creating a custom profile, you can fine-tune your printer for what matters most to your specific application, whether it's maximizing speed, ensuring impeccable detail for prototyping, or optimizing for mechanical strength.

- Material Specificity: Every filament and resin has different optimal temperatures, cure times, and shrinkage properties. Custom profiles allow you to match your settings precisely to your material.

- Print Quality: Fine-tuning settings like layer height and line width (for FDM) or exposure time (for SLA) can drastically improve the surface finish and aesthetic of a print, giving it a professional, polished look.

- Mechanical Properties: For functional parts, adjusting infill patterns, wall thickness, and print speed directly impacts the part's strength and durability, ensuring it can withstand real-world stress.

Key Settings for FDM and SLA

The following are some of the most important parameters to adjust when building a custom profile for each technology:

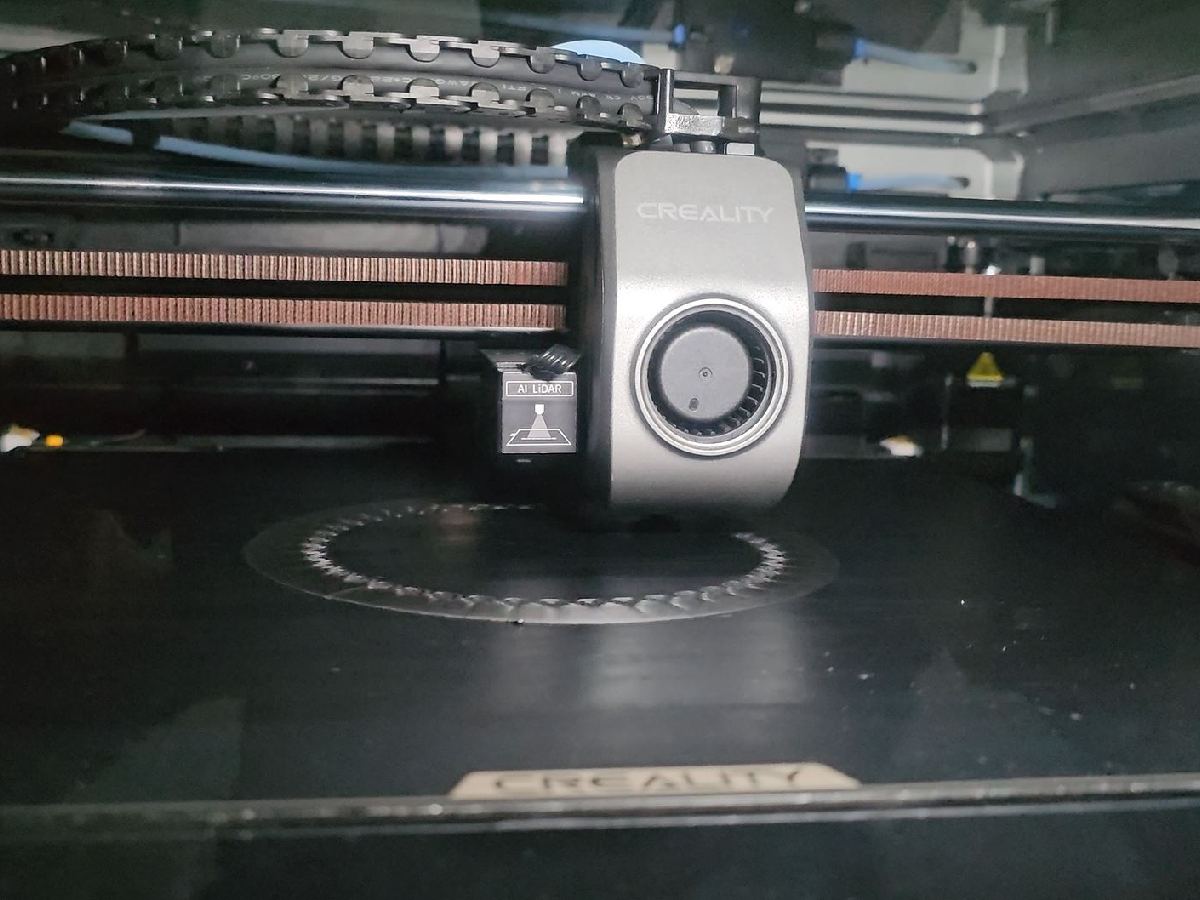

For Fused Deposition Modeling (FDM):

- Temperature: Nozzle and bed temperatures are critical. Too low, and you risk poor layer adhesion; too high, and you can cause warping or stringing. It’s best to perform a temperature tower test for each new filament to find the perfect balance.

- Retraction Settings: These settings control how much filament is pulled back into the nozzle during non-printing moves. Proper retraction prevents unsightly stringing and blobbing, leading to a cleaner, more precise print.

- Print Speed: While it's tempting to print as fast as possible, slowing down can improve print quality and adhesion, especially for intricate details. Conversely, faster speeds can be used for prototypes where quality is less of a concern.

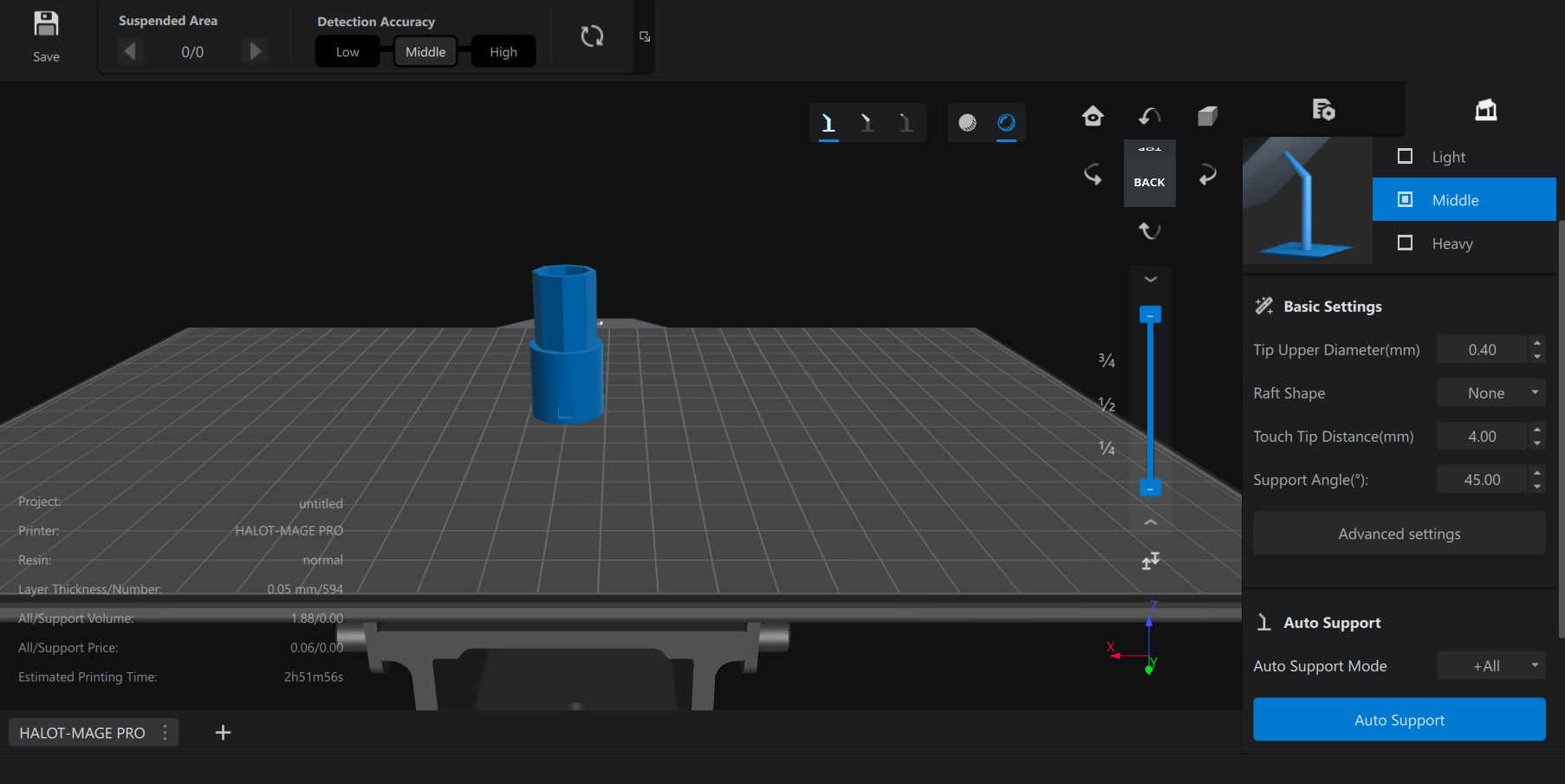

For Stereolithography (SLA):

- Layer Exposure Time: This is the most crucial setting for SLA. It dictates how long each layer of resin is exposed to UV light, which directly impacts the part's accuracy and hardness. Finding the ideal exposure time is key to a successful print.

- Lift Speed: The lift speed determines how quickly the build plate lifts from the resin vat after a layer is cured. Too fast, and you risk print failures from suction forces; too slow, and your print times can increase significantly.

- Retraction Speed: This controls how quickly the build plate moves back down. A carefully tuned retraction speed ensures the resin has enough time to flow back into the space between the build plate and the vat's film, preventing air bubbles and inconsistencies.

Our Expertise and Global Presence

At Agratis Print Workshop, we have spent countless hours developing and testing custom profiles for a variety of filaments and resins. This expertise allows us to provide you with tailored solutions for consistent and reliable results, whether for a single part or for high-volume batch production.

In addition to our work in Europe, we also operate our American branch, Agratis Horizon Inc US, which focuses on the American market. You can learn more about their services by visiting their website at agratishorizon.uk.

If you're ready to elevate your 3D printing projects, don't hesitate to reach out. Our team of experts is here to help you navigate the complexities of custom profiles and achieve the best possible results.