Carbon fiber infusion is an advanced post-processing technique that can significantly enhance the mechanical properties of 3D-printed parts. By infusing a porous 3D printed object with a carbon fiber-filled resin, you can drastically increase its strength, stiffness, and durability. This method is particularly valuable for applications where parts need to withstand high stress or a demanding environment, making it a game-changer for both rapid prototyping and functional part creation.

What is Carbon Resin Infusion?

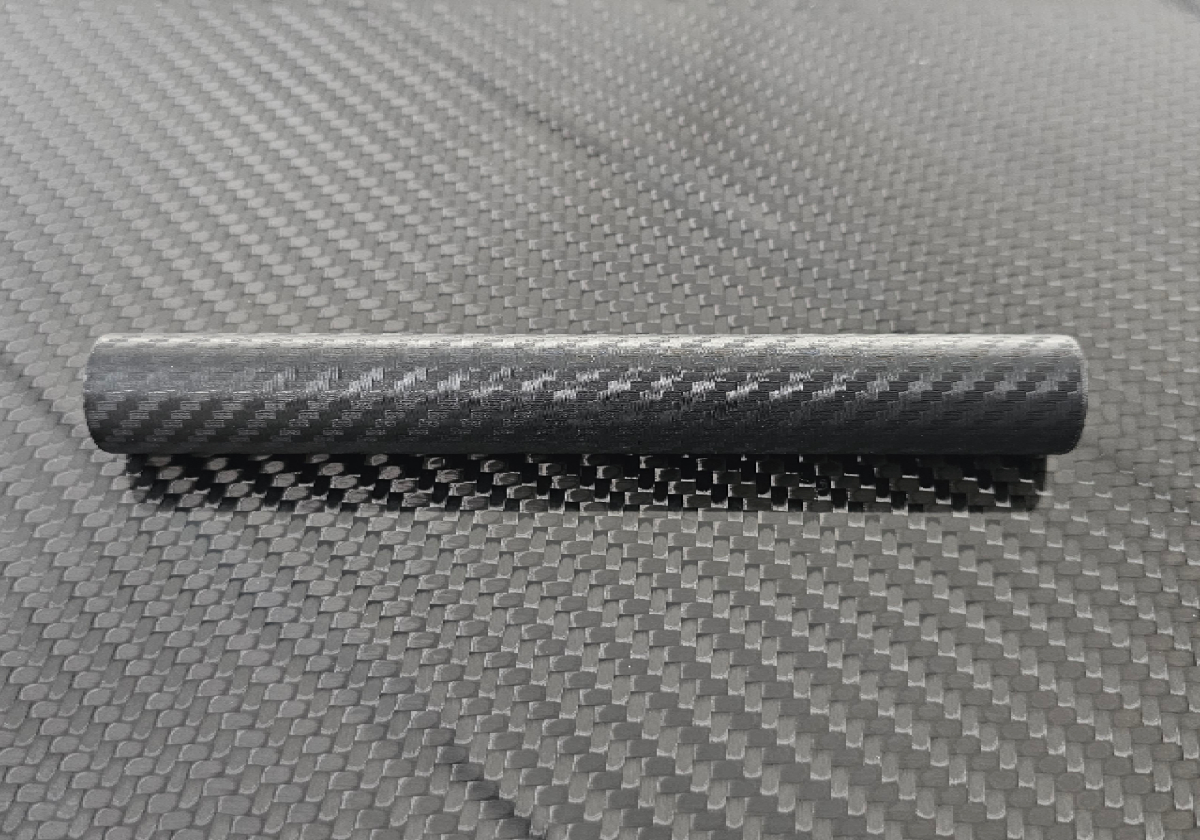

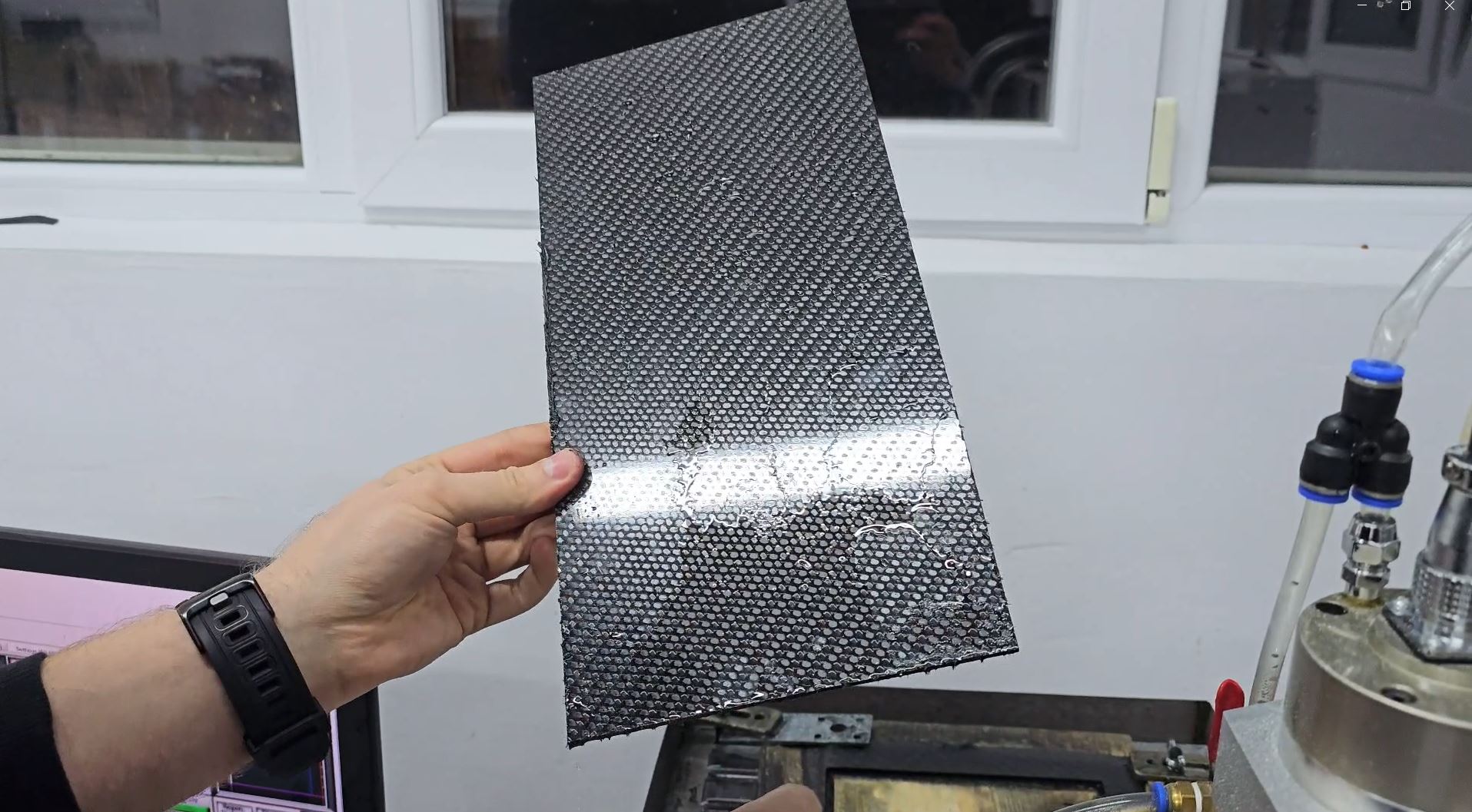

Carbon resin infusion is a process that impregnates a 3D-printed object with a specially formulated liquid resin containing carbon fiber particles. The 3D-printed part, typically created using Fused Deposition Modeling (FDM) with a low-density infill to maximize porosity, acts as a scaffold. The resin, when cured, fills the internal voids of the print, bonding with the plastic and creating a composite material that is far stronger and stiffer than the original part alone.

Benefits of Carbon Resin Infusion

The primary benefit is the dramatic improvement in material properties. Carbon resin-infused parts can exhibit:

- Increased Tensile Strength: The carbon fibers within the resin act as reinforcement, similar to how rebar strengthens concrete. This significantly improves the part's ability to resist pulling forces.

- Enhanced Stiffness: Infusion reduces the flexibility of the part, making it more rigid and less prone to bending or deforming under load.

- Improved Durability: The composite material is more resistant to wear and tear, and less susceptible to environmental degradation from factors like UV light and moisture.

- Reduced Weight: By using a low-infill 3D print as a base, you can achieve a very strong part without the added weight of a completely solid print.

This process is ideal for demanding applications in industries like aerospace, automotive, and robotics, where every gram of weight and every unit of strength counts. It is also an excellent method for creating high-performance prototypes and durable parts for R&D and batch production projects.